Understanding the Difference Between Single Phase and 3 Phase Power

If you’ve ever worked with industrial equipment or processes, then you’re probably familiar with phase concepts. Every piece of motor, generator, or machine requiring 3 phase power has a phase angle associated with it. But what exactly is phase, and what does it have to do with the type of power being used?

The phase of an electrical signal refers to how much a voltage or current lags or leads to another signal. When two different voltage or current sources are combined in a circuit, their phases will differ. The point on the oscilloscope where the two signals intersect is called the ‘phase point.’

This article explains the difference between single-phase power and 3-phase power and why one is better than another for specific applications.

What is single phase power and what is three phase power supply?

In simple terms, we can define single-phase power as the form of power that comes from a single source. It is the most common type of electrical power in use today. The voltage of a single-phase alternating current (AC) waveform is produced by supplying a positive and negative voltage to the circuit. The voltage waveform can be divided into two different waves: one with a positive voltage and one with a negative voltage.

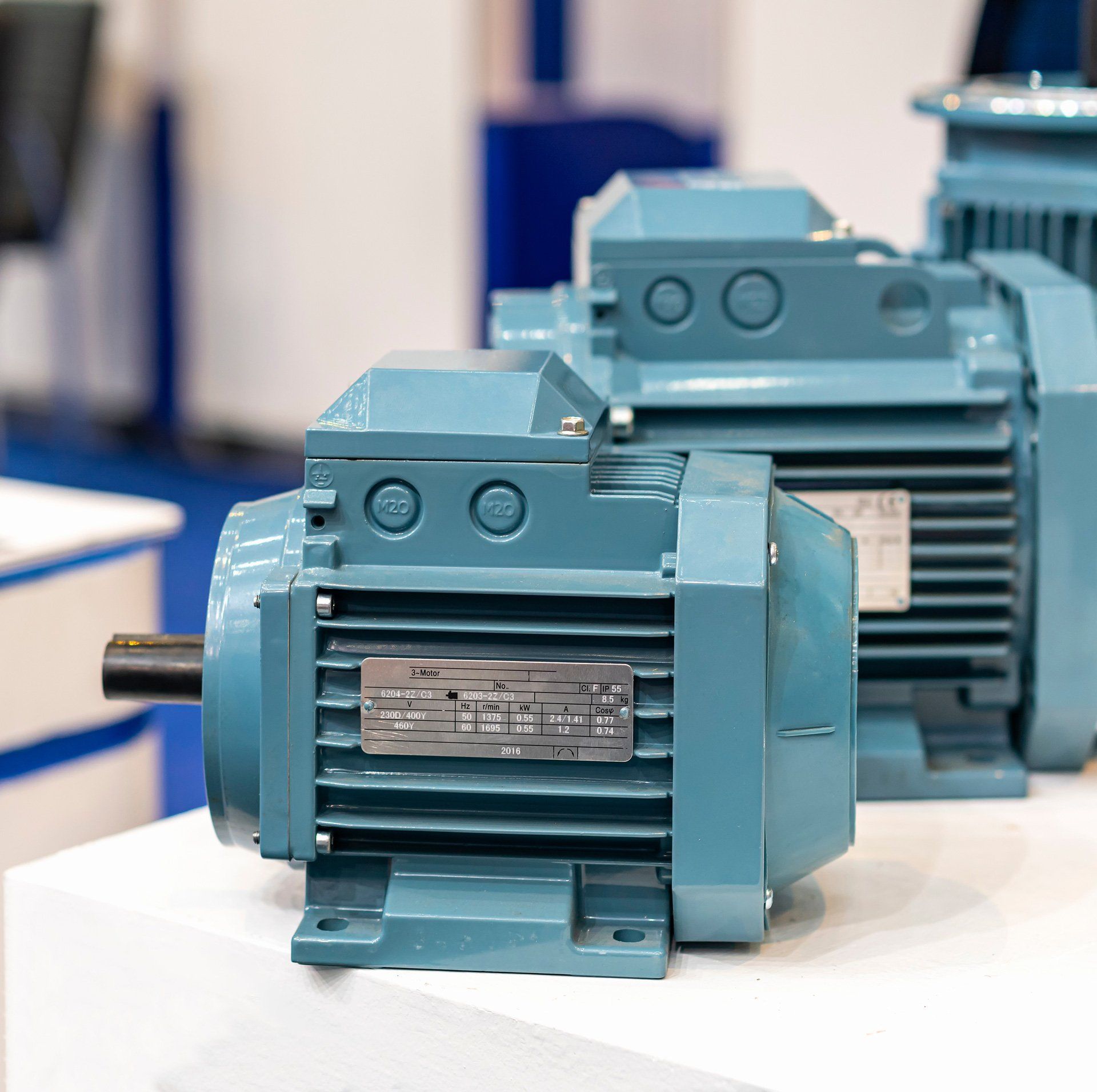

On the other hand, three-phase power is more complicated than single-phase power since it requires at least three separate sources to produce an alternating current (AC). A 3-phase generator needs three different windings to drive it, each set up 120 degrees apart from the other. The three-phase voltage waveform has three different peaks, each separated by 120 degrees. Both supplies will also have a neutral wire that carries the return current back to the source.

Benefits of Using 3 Phase Power

These are the main benefits of using three-phase power:

Increased Amount of Power

A 3-phase system can provide a lot more voltage than a single-phase system, which means more power is available. The 3-phase system can supply up to three times the power a single-phase system can supply.

Easier Flow Energy Control

The three-phase power supply can provide the same amount of power with a smaller conductor size than a single-phase system. This is because the current in a three-phase power supply flows more smoothly than in a single-phase supply.

Better Efficiency

The higher voltage of a three-phase system means that less current is required to transfer the same amount of power. This leads to lower energy losses in the system, which results in improved efficiency.

Importance of 3-Phase Test and Tag

The 3-phase test and tag is a necessary safety procedure that must be completed before the electrical system can be energized. This test verifies that the electrical system has been installed according to the design and meets all of the relevant standards.

A licenced specialist must perform this test, and it is crucial to make sure you hire a licenced specialist for this job. The 3-phase test and tag verify that:

- All of the equipment has been installed correctly.

- All of the equipment is safe to use.

- The work meets all relevant standards for safety, performance, quality, and reliability.

- The work has been inspected to ensure compliance with all relevant standards.

A licenced specialist will complete this task using their knowledge, skills, and experience to ensure that all criteria have been met. It is important not to attempt this task yourself because it could put you or your family at risk if it has not been done correctly or safely.

Many people try to save money by doing as much as they can themselves when it comes to home renovations or repairs, but in some cases, doing so can put your family at risk because you might not know what you are doing or how to do it properly without endangering yourself and others around you.

In most cases, hiring a licenced specialist will cost less than trying DIY methods because they will do a better job in less time than if you tried doing it yourself or with help from friends who may not know how to do it properly.

When is it best to use single phase power instead of 3 phase power?

There are some instances where it is best to use single-phase power instead of 3 phase power. One example is when you power a small appliance such as a toaster or a coffee maker. Another example is when you use a device that does not require a lot of power, such as a laptop computer. Single-phase power is also less expensive to install than three-phase power.

How can you tell if your business needs 3 phase power?

For most businesses, 3-phase power is the only option. The only way to tell if you need 3 phase power is to look at the equipment you need to run your business. If you are running large motors, such as those found in a manufacturing plant, three phase power is likely needed. However, if your equipment runs on a lower voltage and doesn't require much energy, then it could be run on single-phase power supply.

If your business requires a lot of large machinery or equipment, then it's likely that you will need three phase power to supply all of the heavy machinery with enough energy to run properly.

If your business requires three phase supply, you will need several breakers and transformers to supply all of your energy needs. In most cases, this means that you will have multiple circuits coming into one breaker box or transformer, which means that there will be three wires instead of two like with single phase wiring.

Making sure that your business has what it needs in terms of electricity supply is important for making sure everything functions properly and safely, so it's important to make sure that everything has what it needs before trying to get anything up and running otherwise, there could be some issues that pop up.

Test Your Equipment

At ElectroTechnics, we understand the importance of having your equipment regularly tested and tagged. Our 3 phase test and tag service includes:

- Thorough visual inspection

- Earthbound test

- Insulation resistance test

- Earth leakage test

We specialise in providing comprehensive test and tag services to businesses across Greater Sydney, Wollongong, and the Shellharbour region. Our team of licenced specialists have the knowledge and experience to safely and efficiently test and tag all of your electrical equipment.

To find out more about our test and tag services, or to book a free quote,

contact us today.

-

Book Your Safety Today

I hope you enjoy reading this blog post.

ElectroTechnics ensures workplace safety by offering electrical testing and tagging and RCD trip time measurements across Greater Sydney, Wollongong and Shellharbour Region.

I hope you enjoy reading this blog post.

ElectroTechnics ensures workplace safety by offering electrical testing and tagging and RCD trip time measurements across Greater Sydney, Wollongong and Shellharbour Region.

ElectroTechnics Test and Tag is your premium contact for all workplace electrical testing and tagging and RCD trip time measurements.

Browse Our Website

Contact Information

Phone: 02 4063 1452

Serving Greater Sydney, Wollongong and Shellharbour Region.

Locations

Mon-Fri 08:00 AM - 05:30 PM