Test and Tag Sydney and Wollongong Specialists

Peace of Mind Is Everything

ElectroTechnics Test and Tag Sydney and Wollongong is your trusted, reliable partner for electrical appliance testing and tagging, offering a hassle-free, fully managed service for your workplace.

ElectroTechnics Test and Tag provides peace of mind knowing your electrical appliances and equipment are working well and your staff and customers are safe from electrical dangers.

Uphold your duty of care by protecting staff

Reduce the risks of danger in the workplace

Maintain your electrical equipment

Comply with OH&S regulations and the Australian Standard AS/NZS 3760

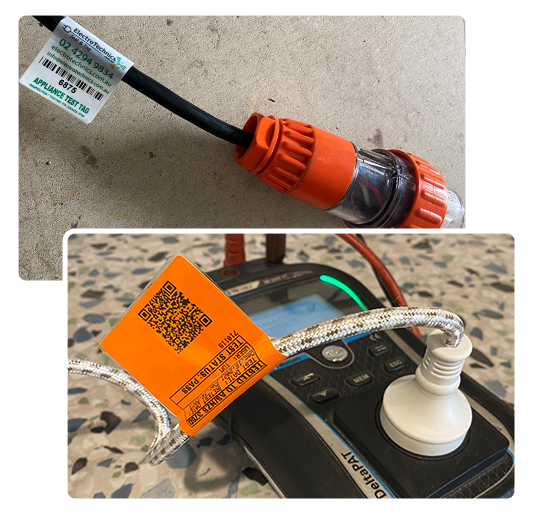

As your premium contact for all electrical testing and tagging and RCD trip time measurements, we conduct annual or bi-annual inspections.

Regular testing of electrical appliances can reduce the risk of accidents in your place of business. Our test and tag services have no lock-in contract, which means you can cancel any time you choose.

For your convenience we also provide plug and cord repairs onsite and stock a range of different plugs and sockets.

WHY CHOOSE ELECTROTECHNICS TEST AND TAG?

AFFORDABLE TEST AND TAG PRICES

We offer premium quality electrical test and tag services at affordable prices.

THOROUGH INSPECTIONS & TESTING

We conduct a thorough visual inspection and testing to ensure your electrical appliances and equipment are safe to use.

EQUIPMENT CHECK & REPAIR SERVICE

We check your items and repair any faulty electrical equipment if it is not a recall.

EXPERT ADVICE

We give expert advice on what to do with the equipment in case of a failure.

DETAILED REPORTS

We provide detailed reporting with comprehensive measurement results so you can conduct pro-active maintenance.

REMINDER CALL

We will give you a call 1 or 2 weeks before your next testing is due to arrange a time that suits you.

NO LOCK-IN CONTRACT

Pause or cancel the contract any time you choose.

FRIENDLY & PROFESSIONAL SERVICE

Our friendly and professional service technicians will get the job done and answer any questions you may have with a smile.

REFERENCES

Delighted customers who are happy for you to contact them as our references.

We aim for ongoing relationships built on trust and great service.

SERVICES

Workplace

Test & Tag

Want to make sure that the electrical appliances you have at work are safe from electrical hazards? We've got you covered. ElectroTechnics provides a formal visual inspection that can find more than 90% of faults and will perform testing and tagging of any electrical plug-in equipment in your workplace to ensure electrical safety and compliance.

3-Phase

Test & Tag

Do you have 3-phase electrical equipment and want to make sure they are in good, safe working order? Would you like to have peace of mind that your business is safe from electrical mishaps? Look no further than ElectroTechnics. We have the most common 3-Phase adapters to test and tag your machinery to ensure safety in your business.

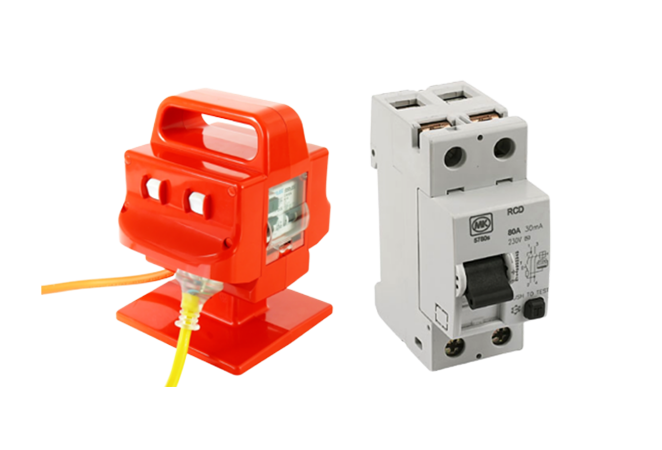

Safety Switch Testing

Have some electrical equipment located in potentially hazardous areas? Workplace injuries and fatalities can be prevented by the use of properly maintained residual current devices. Fixed and portable RCDs used at work should be tested regularly to make sure they are working effectively. ElectroTechnics will inspect, test and tag your workplace safety switches in accordance with the Australian Standard.

Microwave Radiation Testing

Are the microwave ovens at your business safe to use? Would you like to check to make sure they are not emitting radiation? ElectroTechnics is available to assist. As your electrical testing specialists in Sydney and Wollongong, we follow a meticulous step-by-step procedure to check that your workplace microwave ovens are not leaking radiation.

Power Plug Replacement

We also provide plug and cord repairs onsite. For your convenience we stock a range of different quality Clipsal plugs and sockets.

Read Why People Trust Us For Their Test & Tag Needs

Thanks to Tom our center is safe for all our children to attend. Tom checked all our equipment promptly, was able to arrive at a time that suited us and the price was competitive. I would not hesitate in recommending and using Tom again.

S. Beard, Cre8tive Corner Kindergarten

Button

Tom provides a great customer service experience which is hard to find these days. He didn’t over charge and was very accommodating to my needs as a customer. Would recommend Tom for your jobs. Thank you again

E. Marie, Delishause

Button

Tom provided supportive, responsive service. I was very happy with his approach and communication. I would recommend him to anyone as honest and down to earth who strive to achieve the best for his clients!

R. Bahno, Graham Ball Estate Agents

Button

Tom came out to our business and has done a fantastic job with his test and tag of our gear at short notice. We were in desperate need of an electrical appliance testing tradesman and Tom came out same day. Very friendly and professional, also helped me with some other computer issues I had as well at the time. Will definitely use again.

Jonathan Polyblank,Hyworth Forklifts

Button

5 Star service from the time Tom and his crew arrived until the time they left. Presentable, knowledgable, professional, affordable & very tidy – we were more than happy with ElectroTechnics. Would be very happy to recommend.

Perry,Engadine

Button

Schedule Your Workplace’s Electrical Safety Today

ElectroTechnics Test and Tag is your premium contact for all workplace electrical testing and tagging and RCD trip time measurements.

Browse Our Website

Contact Information

Phone: 02 4063 1452

Serving Greater Sydney, Wollongong and Shellharbour Region.

Locations

Mon-Fri 08:00 AM - 05:30 PM