Our TESTING AND TAGGING Services

If an accident happens at your workplace, can you show Worksafe NSW that you did everything in your power to prevent it from happening? If not, you could be in serious trouble!

As a person conducting a business or undertaking (PCBU), you are responsible for making sure that your workplace is safe. Having your plug-in electrical appliances, tools and other equipment tested and tagged regularly is an important workplace safety measure.

We refer to the AS/NZS 3760 recommended testing timetable to see how often we should check your workplace.

We have customers relying on us in all sorts of industries, from kindergartens to high school, from small businesses (shops, mechanics, offices) to multinationals.

We also offer 3 monthly onsite testing and tagging for contractors and tradies on construction sites.

Workplace

Test & Tag

Want to make sure that the electrical appliances and equipment you have at work are safe from electrical hazards? We’ve got you covered. ElectroTechnics provide formal visual inspections which can find more then 90% of faults and test and tag any electrical plug-in equipment in your workplace to ensure electrical safety and compliance.

3-Phase

Test & Tag

Do you have 3-phase equipment and want to make sure they are in good, safe working order? Would you like to have peace of mind that your business is safe from electrical mishaps? Look no further than ElectroTechnics. We have the most common 3-Phase adapters to test and tag your machinery to ensure they’re safe.

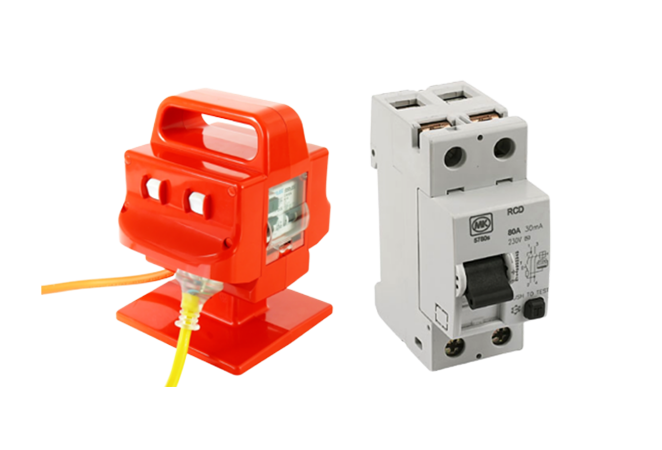

Safety Switch Testing

Have some electrical equipment located in potentially hazardous areas? Workplace injuries and fatalities can be prevented by the use of properly maintained residual current devices. Fixed and portable RCDs used at work should be tested regularly to make sure they are working effectively. ElectroTechnics will inspect, test and tag your workplace safety switches in accordance with Australian Standards.

Microwave Radiation Testing

Are the microwave ovens at your business safe to use? Would you like to check to ensure they are not emitting radiation? ElectroTechnics is available to assist. As your Wollongong electrical testing specialists, we follow a meticulous step-by-step procedure to check that your workplace microwave ovens are not leaking radiation.

Power Plug Replacement

We also provide plug and cord repairs onsite. For your convenience we stock a range of different quality Clipsal plugs and sockets.

If you have any questions about testing and tagging for workplace safety or want a free risk-analysis, please don’t hesitate to contact us.

ElectroTechnics Test and Tag is your premium contact for all workplace electrical testing and tagging and RCD trip time measurements.

Browse Our Website

Contact Information

Phone: 02 4063 1452

Serving Greater Sydney, Wollongong and Shellharbour Region.

Locations

Mon-Fri 08:00 AM - 05:30 PM