What is an RCD and Why Should You Have It Tested Regularly?

Are you in charge of your workplace premises? If so, you have a legal responsibility to make sure that the electrical system and any appliances are safe to use. RCD testing is one way to do this. But what is an RCD? Keep reading.

Electrical safety is something that we probably don’t think about until something goes wrong. An electrical incident can happen at any moment, but most of the time, you won’t even realise it has happened until it’s too late and you set off your workplace’s residual current device (RCD).

These devices are designed to prevent electrical shock or electrocution in the event of a power failure by automatically switching off the electricity supply to your workplace. Read on to learn more about residual current devices and why you should have yours tested regularly.

What is an RCD?

A residual current device, or RCD, is a safety device that is used in electrical circuits to detect and prevent electrocution. This device immediately shuts off the power supply to an electrical circuit when it detects an imbalance in the current flowing through the circuit. That way, if there is a short circuit or some other problem drawing sudden electrical surges, it won’t cause an electric shock or electrocution.

What are the main types of RCD?

RCDs can save lives, but only if they are working properly. There are four main types of RCDs:

Circuit Breaker

The switch is usually found in the main fuse box/switchboard. Circuit breakers protect all of the lighting circuits in your workplace. Circuit breakers and fuses are designed to stop the flow of electricity if there is a problem or drawing sudden electrical surges. This device prevents electrical fires, not electrocution.

Combination RCD

This combines an RCD with a circuit breaker in one unit. It is designed to protect circuits and electrical appliances from overloading and faults as well as prevent electrocution.

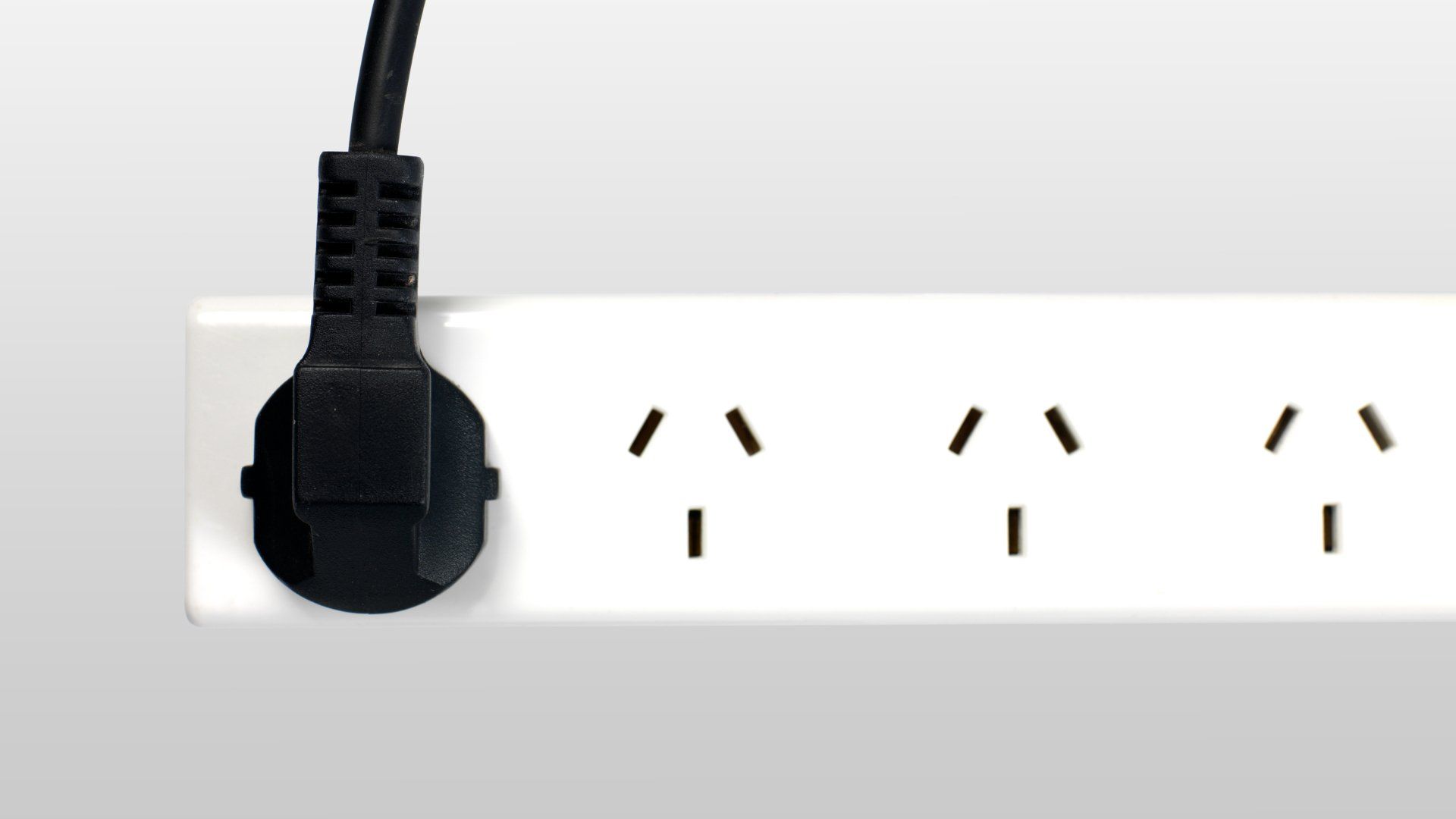

Portable RCDs

As the name suggests, these are designed to be portable and can be plugged into any standard power outlet. They are often used by tradespeople, such as electricians, who need to work with electrical equipment in a variety of locations.

Power Point RCDs

RCD fitted to a power point can be distinguished by a test button on the face plate. Power point RCDs are designed to protect electrical appliances in your bathrooms and workshops.

RCD Testing Requirements

RCD requirements only apply to certain types of electrical work where the equipment is supplied with electricity through a socket outlet (plug-in electrical equipment). These are workplaces with operating conditions where:

- electrical appliance or equipment that is exposed to moisture, heat, vibration, mechanical damage, chemicals or dust

- electrical equipment is moved from one place to another where there's a chance that the equipment will get damaged

- electrical equipment is often moved during its normal use

- electrical appliance or equipment is used in an amusement device

The following are some common instances of electrical equipment that require an RCD:

- hand-held electrical equipment: drills, saws, hair dryers, curling wands, and electric knives

- electrical equipment that is moved while in use: jackhammers, electric lawn mowers, floor polishers, and extension cords

- electrical equipment that is carried between jobs in ways that could cause harm to the equipment: electric welders, electric cement mixers, portable bench saws, and extension cords

When should you test your RCD?

It’s a good idea to test and keep a record of your RCD every three months to make sure it is working properly and ensure that your workplace is safe and compliant with AS/NZS 3760:2010.

How do you know if you have an RCD?

The only way to know if you have an RCD is to open your switchboard and look for a label that says “RCD” or “safety switch”. If you don’t have an RCD, then you should consider having one installed by a qualified specialist.

You can contact iTAGPRO if you're unsure whether or not you have an RCD. We will be quick to identify if your workplace is safe and protected by RCD.

Final Thoughts

RCDs are an important part of any electrical safety system. They are designed to protect people and equipment from electrical accidents and fires. If you have any concerns about the safety of your workplace, then you should have an RCD installed by a qualified specialist.

iTAGPRO can help you comply with AS/NZS 3760:2010 and keep your workplace safe. When we're finished, we'll provide you with an inspection report that includes all of the information you need regarding your RCD.

Call us now on 02 4063 1452 to find out more.

-

Book Your Safety Today

I hope you enjoy reading this blog post.

ElectroTechnics ensures workplace safety by offering electrical testing and tagging and RCD trip time measurements across Greater Sydney, Wollongong and Shellharbour Region.

I hope you enjoy reading this blog post.

ElectroTechnics ensures workplace safety by offering electrical testing and tagging and RCD trip time measurements across Greater Sydney, Wollongong and Shellharbour Region.

ElectroTechnics Test and Tag is your premium contact for all workplace electrical testing and tagging and RCD trip time measurements.

Browse Our Website

Contact Information

Phone: 02 4063 1452

Serving Greater Sydney, Wollongong and Shellharbour Region.

Locations

Mon-Fri 08:00 AM - 05:30 PM